Protective cases may not grab headlines, but they quietly decide whether your gear lasts years or fails after one trip. From gun ranges to factory floors to frozen campsites, a good case takes the beating so your tools don’t. The details—foam density, shell thickness, latches—matter more than people think.

Why Protective Cases Matter for Every Application

Anyone who’s ever shipped an expensive rifle or server knows one thing: things get rough on the road. Cases built for protection keep the chaos outside. Each field—tactical, electrical, mechanical, outdoor—needs a different kind of defense.

Firearms and Tactical Gear Protection

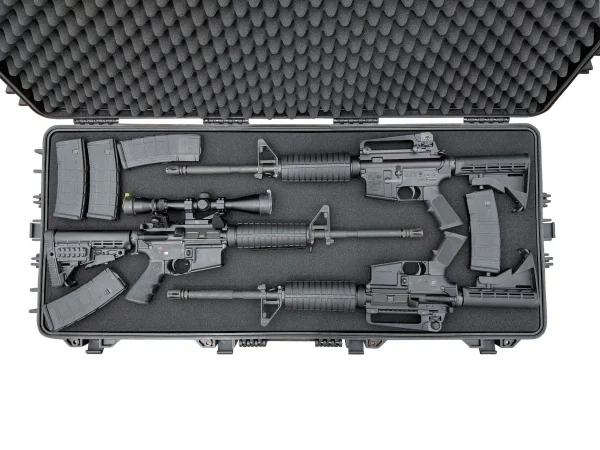

Protective gun cases aren’t about looks; they’re about trust. Inside airports, on dusty truck beds, or during field drills, they take hits so weapons stay zeroed. Handguns, rifles, optics—all need snug foam and solid shells.

Hard-sided designs with dense inserts prevent corrosion and slippage. A case that rattles in transit usually means a scope knocked off alignment later. Many users prefer dual-lock systems and pressure valves; at 30,000 feet, even air pressure can mess with seals.

More about compliance and design updates can be found in the TSA-approved gun case standards for 2025. And if you’ve ever debated between firmer or softer padding, check PE vs PU foam materials for gun cases. The wrong foam can make your gear feel like it’s traveling in a shoebox.

Electronics and Server Equipment

Electronic gear isn’t built for turbulence. One good bump can cost thousands in downtime. Protective cases for servers, routers, and testing instruments are fitted with shock-damping panels and static-resistant lining. Some even have grounding straps inside.

Rack mount protective cases follow a precise rhythm—1U, 2U, 3U—like rows of instruments in a band. When cases are too shallow, cables bend; too deep, and you’re hauling extra air. For better setup math, the 1U and 2U server case dimensions guide explains how pros plan layouts before they hit the road.

A technician once said, “One forgotten airflow vent cost us a motherboard.” That pretty much sums it up.

Tools, Workshop, and Industrial Use

In workshops, accidents are just part of the soundtrack. A wrench drops, a spray of coolant hits the floor, something rolls under a machine. Protective tool cases are the difference between chaos and continuity. Modular ones let mechanics swap inserts when gear changes; fixed ones are for lifers who stick to a single setup.

Materials with chemical resistance, thick corners, and smooth hinges take years of knocks. See the tool organizer guide for how industrial crews cut downtime just by labeling better and sorting foam layouts more sensibly.

Outdoor and Camping Storage Solutions

Rain, dust, cold, heat—outdoors rarely takes it easy. Cameras, first-aid kits, cooking stoves—everything needs its place. Waterproof protective cases with IP67 ratings are a safe bet; they handle being dropped in mud puddles or left overnight in frost.

Corrosion-resistant seals and vacuum gaskets are lifesavers in coastal regions where salty air chews through metal. For extreme temperatures, the cold-weather cooler guide shows insulation tests that keep gear usable even at −20 °C.

Understanding Case Materials and Construction

A protective case is only as strong as its materials. Cheap foam or brittle shells can ruin thousand-dollar equipment faster than you’d expect.

PE vs PU Foam: What’s the Difference and When to Use Each

PE foam feels firm, like memory that doesn’t forget shape. It’s great for rifles, torque wrenches, or anything heavy. PU foam, softer and more elastic, fits lighter tools or lenses that need gentle handling. Many manufacturers blend both to get balance—PE for the base, PU for the top layer.

The wrong choice often shows up months later as sagging slots or cracked edges.

Plastic vs Aluminum Shells: Durability and Weight Comparison

Plastic protective cases—usually polypropylene or ABS—are lighter, cheaper, and fine for most users. Aluminum brings heat resistance and more crush strength. Military contractors often choose aluminum, even though it adds 20–30% extra weight. For weekend photographers or traveling engineers, plastic does the job without extra baggage.

IP Ratings, Shock Absorption, and Environmental Resistance

An IP rating tells you how much abuse a case can take from dust and water. IP67 is common—1 meter underwater for 30 minutes with no leaks. Add layered foams and rubber seals, and vibration barely gets through. Outdoor contractors and survey teams swear by these features; dust storms or cargo bay moisture can wreck electronics in hours.

When gear costs more than your car, waterproof isn’t optional—it’s insurance.

Common Design Mistakes and How to Avoid Them

People assume all protective cases are tough. Then reality shakes the truck.

Structural Weaknesses in Plastic Rack Mount Cases

Thin corners and rails are classic weak spots. One rough shipment, and the crack spreads like glass. Internal aluminum framing can double structural life without adding much weight.

For real-world examples of what goes wrong, check 5 design mistakes that ruin your rack mount case—and how to fix them.

Poor Ventilation and Overheating Risks

Sealed cases look clean but trap heat. Without intake and exhaust paths, temperatures can climb fast, especially in data transport. Overheated gear smells like burnt dust before it fails.

Foam Layout and Weight Distribution Errors

Uneven foam layouts cause gear to shift mid-transport. Every move grinds down corners or scratches finishes. Balanced spacing fixes it. Think of it as packing a suitcase—you’ll know when something’s off by how it sits.

How to Redesign a Case for Better Stability

Simple upgrades—rubber feet, heavier hinges, better locks—turn a shaky case into a solid travel partner. Off-road surveyors even add thin rubber mats under cases to cut vibration noise in vehicle storage.

Choosing the Right Case for Firearms and Tactical Transport

TSA-Approved Gun Case Standards in 2025

The TSA rules didn’t change much, but enforcement did. Gun cases must be hard-sided, fully lockable, and owner-access only. Ammunition has to travel separate. One misstep and security will delay your flight—people have learned this the hard way.

Always double-check requirements using TSA gun case guide before packing.

Locking Systems, Air Valves, and Travel Compliance

Good locks save headaches. Combo locks fit frequent travelers; keyed ones suit controlled armories. Pressure valves? They stop cases from ballooning when air pressure shifts. A minor feature until your case won’t open mid-trip.

Custom Foam Inserts for Firearm Safety

Properly cut foam holds every component—barrel, scope, grip—in place. Foam that’s too soft lets items slide; too stiff makes reloading it a fight. Gun owners often mark cutouts with chalk first before trimming to avoid wasting material.

How to Pack Firearms for Airline Travel

Unload weapons, remove magazines, separate ammunition. Secure everything in labeled containers inside a locked protective case. Declare it at the counter; airline staff handle these situations daily. It’s better to arrive early and avoid awkward explanations later.

Storage and Organization for Tools and Accessories

Modular Tool Organizers vs Fixed Compartments

Some technicians treat their cases like puzzles—each tool has its spot. Modular systems allow quick changes when new gear comes in. Fixed ones resist bending and are fine for long-term setups.

How to Keep Tools Sorted and Protected

Dust and rust don’t mix with precision tools. A small silica gel pack works wonders. Technicians often tape spares to the lid for quick swaps. Keeping things dry prevents surprise oxidation after rainy job days.

Smart Labeling and Inventory Systems

Color coding, QR stickers, even a Sharpie works if used consistently. Inventory tracking isn’t fancy—it’s just habit. A case labeled “hydraulic tools” saves minutes that add up over a month.

Understanding Server Rack Units and Case Dimensions

What 1U and 2U Mean in Rack Mount Standards

Rack unit math: 1 U = 1.75 inches. That’s it. Get it wrong, and your gear won’t fit. Most protective rack mount cases follow the 19-inch width standard. Always check both height and rear clearance.

Case Sizing for Network and Audio Equipment

Cables are the usual culprits. Too short, and connectors pull; too long, and they snag. A 2U case might seem big enough until you realize the plug extends another inch.

Planning Rack Layouts for Port Access and Cooling

Hot air should never blow straight into the next unit. One blank panel between servers helps airflow. Portable racks need cable arms that don’t pinch when the lid closes. These are small details that save large repair bills.

Outdoor and Extreme Condition Protection

Choosing the Right Cooler for Cold Weather Use

Double-insulated coolers keep temperatures steady even after hours in the back of a pickup. Some models tested up to 72 hours below freezing without losing internal chill. That’s what matters when transporting lab samples or hunting provisions.

Temperature Control and Insulation Materials

EPS and vacuum panels work like thermos layers. They’re lighter than you’d expect and cut down heat exchange dramatically. Researchers and rescue teams rely on them because food or meds can’t fail mid-mission.

Water, Dust, and Impact Resistance in Outdoor Cases

Protective outdoor cases need tight seals and corrosion-resistant hardware. After weeks of exposure to sand and moisture, the difference between a sealed latch and a loose one can be rusted hinges. A small silicone bead around the gasket edge often adds years to service life.

Conclusion: Matching the Right Case to the Right Task

Quick Reference by Use Scenario

- Firearms: Hard-sided protective gun cases with custom foam and TSA locks.

- Tools: Modular cases, rust-resistant interiors, silica gel pouches.

- Servers: Rack mount protective cases with proper airflow and cable clearance.

- Outdoors: IP-rated, insulated shells for harsh climates and long hauls.

Key Takeaways for 2025 Buyers

Protective cases in 2025 aren’t just tougher—they’re smarter. Expect denser foams, lighter frames, and easier repairs. Pick cases that match the real environment, not the catalog photo. Spending 10 % more upfront saves replacements later.

Explore Our Full Range of Protective Case Solutions

IFSTAR builds protective cases for people who move gear, not just store it. From firearm transport to data-center rigs to expedition equipment, every case is field-tested and built to last.

Explore IFSTAR’s protective case lineup to keep your tools, electronics, and instruments safe no matter where the job takes you.

FAQ

Q: How long do protective cases usually last?

A: Most protective cases hold up for 5–10 years. The shell rarely fails first — the foam does. After a few years, it can flatten or absorb moisture. Replacing inserts every few seasons keeps the case working like new.

Q: Can a protective case be repaired instead of replaced?

A: Yes. Most pro-grade cases let you swap seals, locks, or hinges. Many users keep spare parts around for quick fixes. IFSTAR even offers wheel and latch kits so the case stays useful for years.

Q: What is the best foam type for fragile electronics?

A: PU foam is softer and cushions light gear like cameras or testers. PE foam is denser and better for heavier tools or firearms. Some kits use both — firm PE below, soft PU on top.

Q: Are protective cases waterproof and dustproof by default?

A: Not all of them. Only IP-rated models truly seal out water and dirt. IP67 means short submersion is fine; IP54 just handles splashes. Always check the label before heading outdoors.